EVOLUTIVE means going one step further in eyewear design and manufacturing. It is not about trends or seasonal collections — it is about creating concepts that adapt, transform, and endure.

With our own ROUNDTEN Factory, we control every stage of the process: from materials and prototyping to production and delivery. This gives us the freedom to innovate, to experiment, and to push technology where no one else dares.

EVOLUTIVE is the fusion of creativity and precision engineering.

Frames that are lighter, stronger, and timeless. Eyewear designed to evolve with you.

MATERIALS

The core of ROUNDTEN is Flextal®, our registered alloy: impact-resistant, rust-proof, hypoallergenic, and highly adaptable.

We also master the elegance of high-end acetate, combining aesthetics with flexibility.

And in 2025, we take a new step forward with Japanese titanium: ultra-light, precise, and virtually indestructible.

FLEXTAL® METAL

ACETATE

JAPANESE TITANIUM

FLEXTAL® METAL

Unlike other steels on the market, Flextal® has minimal memory, allowing us to adjust nose pads, pantoscopic angles, and temples without them returning to their original shape.

Most importantly: no tools, no screws, no weak points.

View more

ACETATE

Our acetate frames combine a refined acetate front with internal Flextal® temples, fully covered for flexibility, strength, and comfort. The hinge? Always the same: Metal-Lock® — no screws, no wear, no complications.

View more

JAPANESE TITANIUM

Pure titanium brings millimetric precision, minimalist aesthetics, and an unmatched tactile feel. Combined with ROUNDTEN’s modular functionality, the result is probably the most advanced frame on the market. No screws. No limits.

View more

FLEXTAL® METAL

Unlike other steels on the market, Flextal® has minimal memory, allowing us to adjust nose pads, pantoscopic angles, and temples without them returning to their original shape.

Most importantly: no tools, no screws, no weak points.

View more

It all started with one idea: to create a truly durable, lightweight, and maintenance-free pair of glasses. That’s how Flextal® was born—a registered high-carbon medical stainless steel alloy enriched with titanium. A material designed to last, adapt, and perform.

Unlike other steels on the market, Flextal® has minimal memory, allowing us to adjust nose pads, pantoscopic angles, and temples without them returning to their original shape. And most importantly: no tools, no screws, no weak points.

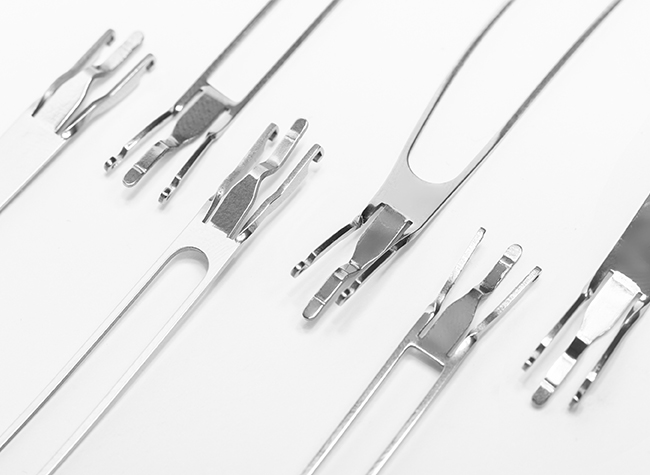

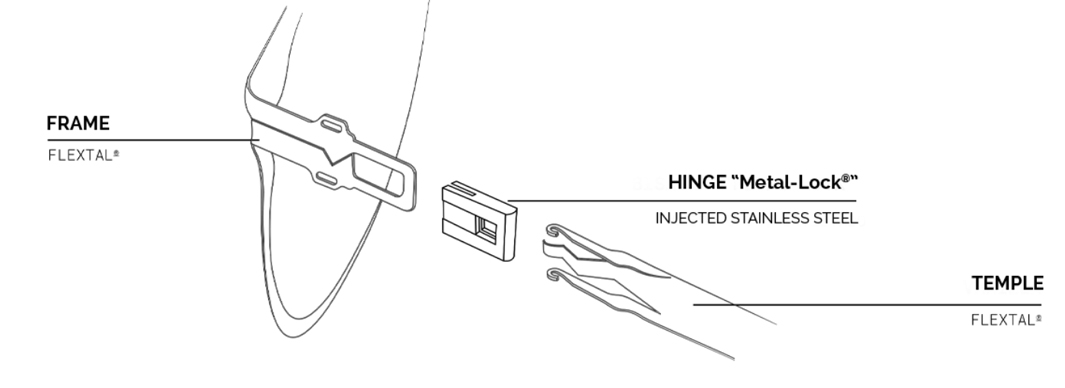

Our patented Metal Lock hinge acts as a single-piece hardened steel anchor. It’s discreet, robust, and unbreakable.

The entire structure of our glasses relies on this system: a modular design, solder-free, 100% interchangeable, engineered to optimize both assembly and repairs.

All this, combined with our PVD (Physical Vapor Deposition) coloring process offers a unique adhesion and resistance to usage and, unlike traditional coatings, our process respects the environment. This completes the formula of high precision materials of our glasses which together with Flextal®, polyamide lenses and our hinge system are extremely robust.

ACETATE

Our acetate frames combine a refined acetate front with internal Flextal® temples, fully covered for flexibility, strength, and comfort. The hinge? Always the same: Metal-Lock® — no screws, no wear, no complications.

View more

JAPANESE TITANIUM

Pure titanium brings millimetric precision, minimalist aesthetics, and an unmatched tactile feel. Combined with ROUNDTEN’s modular functionality, the result is probably the most advanced frame on the market. No screws. No limits.

View more

After mastering Flextal® and reinventing acetate, the next step was natural: our most exclusive collection, crafted from authentic Japanese titanium (not beta—real titanium).

This series leverages all the engineering behind the Metal Lock system to take it to the next level. We combine the world’s best material—lightweight, hypoallergenic, indestructible—with our screw-free hinge, creating frames that not only endure everything but do so with style.

Millimetric precision, minimalist aesthetics, and the pure feel of titanium merge with the modular functionality that defines Roundten. The result is arguably the most advanced frame on the market. No screws. No limits.

Metal-Lock® HINGE SYSTEM

Our Metal-Lock® hinge system is revolutionary: it does not require screws, welds or tools.

The best part? It not only withstands extreme pressure without breaking or bending, but also makes the assembly and disassembly of lenses easier than ever.

LENSES

All our lenses are made of polyamide, combining extreme lightness, elasticity, and unmatched scratch resistance—perfectly paired with Flextal®. They feature standard high-quality treatments, many integrated during manufacturing: hard coat, anti-reflective filter, water and oil repellent, polarized, and certified protection.

The ROUNDTEN Metal-Lock® Hinge is more than a component — it’s a reference of our technology and the true hallmark of ROUNDTEN. Roundten Technology. Built to last.

WHAT TREATMENTS ENSURE THE HIGH QUALITY AND PROTECTION OF ROUNDTEN LENSES?

HARD-COAT

The most advanced and eco-friendly technique designed to extend the life of your lenses. This treatment strengthens the surface of polyamide lenses, making them significantly more resistant to everyday scratches and wear.

ANTI-REFLEX FILTER

This is the filter that protects our eyes. All our lenses have them and thus the UV radiation that can enter the interior of the lens, and the light and reflections that come from behind, do not reach the eyes, preventing discomfort and risks.

H2O & OIL REPELLENT

ROUNDTEN lenses repel water and oil, avoiding water droplet marks and reducing finger traces, so unpleasant and common on most lenses. This also facilitates visibility and cleaning. All ROUNDTEN lenses incorporate this treatment inside and outside.

POLARIZED

ROUNDTEN lenses go a step further: their polarized filter blocks horizontal glare from surfaces like water, snow, and asphalt, letting only vertical light pass. The result is drastically reduced reflections, enhanced contrast and colors, and a sharper, more comfortable vision—perfect for outdoor activities and driving.